Argentine Crop and Export Limitations and Advantages

Crop Travel Revealed Limitations and Advantages of Argentine Agriculture

February 13, 2008, Wednesday

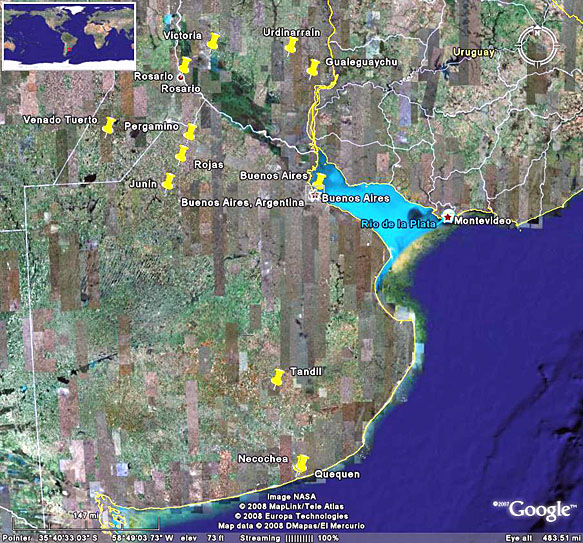

FAS travelers met with representatives of the Bolsa de Cereales in Buenos Aires. They met with individuals involved with daily public relations, production information for marketing and weather information affecting the commodities. With this meeting, a sense was gained of current crop conditions and the extensive network Bolsa has in connection with farmers country-wide and their operations. Bolsa de Cereales contacts producers, elevator owners, port operators and others for information on crop condition and constraints on yield besides also going out and reviewing crop activities and conditions on a weekly basis. Their economic reports include information on area, yield and percent planted or harvested. It also includes information on precipitation, temperature and any other weather that might affect crop yield. They also have used remote sensing within their reporting using their contract with CONAS, the local space agency. They have also begun using short term forecasts (five-day outlooks and 10-day forecasts) for additional information in several of their publications. Their information includes a weekly bulletin on crop progress, a weekly weather report, a producer bulletin and online summaries. Some of the information provided by Bolsa de Cereales fills in information gaps on weather and harvesting that is not always provided by other sources. In general crops were proceeding well through the season, but this season was not expected to be a bumper year like last year.

February 14th, Thursday

The travelers went to Tandil in southern Buenos Aires Province and met with an agronomist employed by Ceres Tolvas. Ceres Tolvas is one of many farming entities similar in structure to a U.S. limited liability corporation. With this type of farming entity, five to fifteen farmers provide land, equipment and supplies along with payment to advisors to develop a stronger block of farms that can sell in larger quantities.

This is very similar to some of the corporations developed along the coast of Texas in the late 1980s and early 1990s with rice farmers in which these larger production sets can better manage, farm, lease and handle grain as well as market their product more efficiently. Quite diverse land management is required around the Tandil area. Within this area, the soil has an under-layer of caliche that makes water management and thus crop management more difficult.

This is very similar to some of the corporations developed along the coast of Texas in the late 1980s and early 1990s with rice farmers in which these larger production sets can better manage, farm, lease and handle grain as well as market their product more efficiently. Quite diverse land management is required around the Tandil area. Within this area, the soil has an under-layer of caliche that makes water management and thus crop management more difficult.

This region with unusual soil constraints within Argentina is known as the Tosco. Sunflowers, soybeans, corn, wheat stubble and unique arrangements of double cropping and intercropping were seen that are experiments being carried out by Ceres Tolvas. Some second crop soybeans were planted either late or not planted in some harvested wheat fields. The crops in general were in good shape for that time of the season; however, dryness was causing spots in some fields to have shorter soybeans because of limited water holding capacity in this Tosco area.

This region with unusual soil constraints within Argentina is known as the Tosco. Sunflowers, soybeans, corn, wheat stubble and unique arrangements of double cropping and intercropping were seen that are experiments being carried out by Ceres Tolvas. Some second crop soybeans were planted either late or not planted in some harvested wheat fields. The crops in general were in good shape for that time of the season; however, dryness was causing spots in some fields to have shorter soybeans because of limited water holding capacity in this Tosco area.

The travelers then proceeded toward Necochea for a tour at Quequen, one of the southern ports. This port is in a southern location with direct access to ocean transport. Because it is not limited by water channel depth, ships can be completely loaded prior to departure. Quequen has concrete elevators, similar to the storage seen in the United States. While this port is capable of complete ship loading, it does not have the most modern transfer system for loading grain from the storage elevators to the ships. It takes over a day to load a Panamax at this port; however, expansion plans for improving and enlarging the facilities are in the works.

February 15th, Friday

Storage capacity is fairly large—comparable to large grain elevators in the Texas Panhandle, though this facility is aging. The location, away from the bustling main corridor of the Parana River and Rosario, limits potential. Grain from southern Buenos Aires and southern Cordoba as well as from the La Pampa region utilizes this port. Infrastructure nearer Rosario will probably be revamped first before this port.

Near the coastal region of Necochea, the team visited a Cargill grain and oilseed plant. Like the grain port at Quequen, the Cargill facility is also in the process of improving storage and grain handling capabilities. Already one of the key ports for grain movement out of southern Argentina, improvement of storage could easily double or triple capacity. The manager also supervises Cargill operations in Paraguay. Cargill has some direct shipments from Paraguay into crushing plants in Argentina with most of the shipments directly to the Cargill facility on the Parana River. The Necochea facility exports soybean oil and packages meal for animal feed. Some expansion of the facility is possible with the land available; however, expansion in Paraguay and Uruguay is more probable.

From Necochea, the travelers headed toward Miramar in order to visit Las Cortaderas, an estancia (large farm and ranch) near the coast. At this farm, corn was being harvested and extensive improvements had been made. Some soybean variety-increases are grown for commercial seed under extensive pivot irrigation systems. This estancia is isolated and still maintains some of the original herd of cattle the ranch is know for in the region. They also maintain an Arabian horse program within the ranch. Both first crop and second crop soybeans were well tended and within large tracts of newly developed land. Traveling across the farm, we came across some slight variation in soil type with various trials and changes in date-of-planting experiments run by the agronomist that also manages much of the farm. Extensive soil tests and changes in operations with new equipment and storage facilities were common across the farm. More plans exist for conversion of pasture to cropland. Much of this farm is intensively cropped up to the tree ridge that signals the coastline which runs along one side of the farm. Sorghum fields dotted areas where soil was less productive, but limited weeds or insect problems were seen. It was explained that chemical pesticides are easy to use and provide good returns in Argentina. Cropping problems were discussed, such as the Green Parrots, that must be controlled in sorghum and the green caterpillars that are sprayed for in soybeans as well as the difficulty in obtaining quick soil sample results from local laboratories. Many samples from the extensive soil sampling done at this farm are sent to the United States. The manager believes that samples are not tested as thoroughly as in the United States, with the accuracy of recommendations suffering as a result.

February 17th, Sunday

The team visited the headquarters of AGD (Alimentos Naturales), the largest peanut processor in the country. They process oilseed crops for export, and go as far as to manufacture their own bottles for the processed oil. At their processing plant, additional storage and refrigerated storage had been added in the past year. The system is similar to facilities in the United States with automatic peanut sorters used after the peanuts have been dried. AGD was in the process of improving the drying facilities by incorporating larger automatic drying systems within some storage areas. Previously, individual peanut trailers had simply hooked up to individual dryer connections under a covered shed in order to process and dry peanuts as they came into the plant. They moved peanuts or processed them into oil within 6 months of harvest before the new refrigeration barn was added last year. Now, with this facility, they are able to run exports year round and utilize peanuts stored in non-refrigerated areas first. Many improvements had been added recently, giving a sense that the industry is slightly growing and has found additional export markets. Much of the production goes into the European Union and into candy. The company is improving it's focus on the market's high end as it has a newly created confectionary peanut program.

The Argentine peanut industry is cautious in their expansion plans, but has found a niche in the confectionary industry overseas. It is diversified in exporting whole peanuts as well as producing oil. Argentines eat neither peanuts nor peanut butter, thus AGD believes an export market for whole peanuts is essential for continued expansion of production.

February 18th, Monday

The travelers stopped at the family farm corporation known as Berardo Agropecuaria in Urdinarrain. The headquarters, machinery, chemical, grain storage and other operations of this sunflower, soybean, and corn farm are manned by a large family of employees. Like many farms in Argentina, this farm uses the same type of equipment and storage bags for their grain as is used in the United States for dairy silage. However, a separate equipment attachment in Argentina

allows the grains or seed to be pulled out of the bags for transfer into a truck when needed for delivery to market or for on farm use. This operation also has some grain storage other than storage bags. The farm employs an integrated pest management agronomist who helps manage the use of seed treatment and other chemicals for better yields. Berardo Agropecuaria pulls in the resources needed for the whole farm operation somewhat differently than in the United States where farms rely on a more service-oriented supply system. On larger farms and corporations in Argentina, many of the larger farms and corporations have all the sprayers, seed treatment equipment as well as chemicals needed for the operation in-house, and they do not have to rely on custom operators. This farm does not have a tight concentric location and has added additional land acquired from nearby smaller-sized farms over the last two years.

allows the grains or seed to be pulled out of the bags for transfer into a truck when needed for delivery to market or for on farm use. This operation also has some grain storage other than storage bags. The farm employs an integrated pest management agronomist who helps manage the use of seed treatment and other chemicals for better yields. Berardo Agropecuaria pulls in the resources needed for the whole farm operation somewhat differently than in the United States where farms rely on a more service-oriented supply system. On larger farms and corporations in Argentina, many of the larger farms and corporations have all the sprayers, seed treatment equipment as well as chemicals needed for the operation in-house, and they do not have to rely on custom operators. This farm does not have a tight concentric location and has added additional land acquired from nearby smaller-sized farms over the last two years.

Estancia Las Cabezas is a farm and ranch that grows corn, soybeans, sunflowers, and sorghum. Near Victoria, Argentina, it has some pastureland—but conversion to cropland is being considered. Some of it's cattle herd is from the original Hereford cattle first brought to this region. Intensive farming along with modern equipment and irrigation has increased crop productivity. This farm uses quality farm equipment with conventional tillage practices, and has opted away from no-till or even minimum tillage. Much of the equipment here carries the John Deere brand. The farm relies mostly on seed plate planters because of the poor availability of air planters. With very good soils and no rocks, recently converted pastureland easily produces good crops. Little fertilizer is utilized due to the high quality of the farm's soils. Much of this farm was in soybeans, and plans to convert remaining pastureland suggest that more soybeans may be planted next year.

February 19th, Tuesday

The team traveled to the Bunge crushing plant at Rosario on the Parana River. The facility utilizes hydraulic lifts to raise trucks to a 45 plus degree angle to unload. Most trucks are farm grain trucks with a few being larger semi-trucks. Almost none of the trucks have grain unloading hatches underneath; thus, more time is taken to unload trucks than in many U.S. facilities.

The grain inspection and sampling station of this facility appeared similar to operations at U.S. cooperatives that take samples for grain quality evaluation. At the Bunge plant, additional samples are routed with seed lots for quality control. At the center of the operation is the crushing plant for extracting oil from the soybeans. At the oil quality laboratory the engineers discussed the improvements being made for development of oil for different uses. Staff members at the plant were knowledgeable about issues important to the oilseed industry. They knew about the marketing situation, and were well versed in the status of the crop in the area which was being harvested. They were knowledgeable about the details of shipments between Argentina, Paraguay and Uruguay and national-origin paperwork for exports. They were knowledgeable about the current situation with the farmers and the export tax.

The grain inspection and sampling station of this facility appeared similar to operations at U.S. cooperatives that take samples for grain quality evaluation. At the Bunge plant, additional samples are routed with seed lots for quality control. At the center of the operation is the crushing plant for extracting oil from the soybeans. At the oil quality laboratory the engineers discussed the improvements being made for development of oil for different uses. Staff members at the plant were knowledgeable about issues important to the oilseed industry. They knew about the marketing situation, and were well versed in the status of the crop in the area which was being harvested. They were knowledgeable about the details of shipments between Argentina, Paraguay and Uruguay and national-origin paperwork for exports. They were knowledgeable about the current situation with the farmers and the export tax.

Farmers are blocking roads and preventing delivery of grains and oilseeds to protest government policy of limiting exports through registration requirements and of increasing taxes on exports. The staff discussed the increasing size of the Rosario port for movement of both grain and oil exports. From the top of the facilities headquarters building one could view a Panamax being loaded. With their loading equipment, these ships are filled only three quarters of the way, taken down river and then topped off from one of the southern ports before heading overseas.

Farmers are blocking roads and preventing delivery of grains and oilseeds to protest government policy of limiting exports through registration requirements and of increasing taxes on exports. The staff discussed the increasing size of the Rosario port for movement of both grain and oil exports. From the top of the facilities headquarters building one could view a Panamax being loaded. With their loading equipment, these ships are filled only three quarters of the way, taken down river and then topped off from one of the southern ports before heading overseas.

Up the Parana River a short distance is Terminal 6, the world’s largest crushing and biodiesel plant. Extensive renovation and enlargement of storage facilities has taken place within the last year at Terminal 6. Because this port is the main producer of biodiesel Argentina, it has been developed similar to oil depots in the United States. Large, circular oil holding tanks allow extensive conversion of soybean to biodiesel product that can be held or easily moved into ships or trucks. The railroad along this stretch of the Parana River has also been improved. Privately owned by the plant, the railroad here can dump soy directly into underground storage from bottom hoppers on the railcars that can then move it to the crushing facility and from there it is exported or routed to make biodiesel. Terminal 6 was developed in 1985. It’s a major terminal of the country for exports. Cargill as well as Bunge and AGD ship some supplies through this facility for processing. The operations are computer controlled. This plant receives real time data on stocks and operations. The plant is able to load bulk carriers quickly, even those over 275 meters long with, reportedly, the quickest dispatch in the world. The plant itself has a processing capacity of 19,000 metric tons per day for oil and vegetable protein exports.

A Panamax can be three-quarters loaded within half a day. They are able to unload 600 railcars and up to 2160 trucks per day. It also has a barge unloading facility that can receive grain from upriver producers. The south berth loads grains, extracts protein meals, and extracts vegetable oil and fills ships up to 275 meters long. The north berth was commissioned in March, 1999 and also allows shipment of grain, protein meal, and vegetable oil. It has a barge bulk unloading jetty that is equipped with two grab operating cranes (so containers could also be used). The current company was founded by shareholders in 1996. Its operation started in May, 1998. Module 2 was added in 2005 which allowed oil processing to reach the capacity of 19,000 metric tons per day. This oil is then routed either to the refinery or for direct export. Earlier, the first 56 hectares of land purchased was utilized to build two silos and an elevator in the south berth. The first ship loaded for export was in 1987. The barge unloading facility started in 1990. The newer north berth has a total storage capacity of 730,000 tons for dry products and 400,000 tons of soybeans for processing. A tank farm can store vegetable oils. Capacity as of two years ago was 147,600 tons—statistics for current capacity were not readily available. Work to improve the depth of the Parana River may soon allow the waterway to have an available draught of 34 feet. With this improvement, ships could load full cargoes rather than partial Panamax loads from the Parana River. However, because the Parana River silts so badly, dredging would have to be a continual process. Additional storage and unloading capacity are currently being worked on at Terminal 6. Access to Terminal 6 is provided by more than nine major roads, the Parana River and railway transportation. Shipments of soybeans from Paraguay and Uruguay are from up the river or down the river respectively.

A Panamax can be three-quarters loaded within half a day. They are able to unload 600 railcars and up to 2160 trucks per day. It also has a barge unloading facility that can receive grain from upriver producers. The south berth loads grains, extracts protein meals, and extracts vegetable oil and fills ships up to 275 meters long. The north berth was commissioned in March, 1999 and also allows shipment of grain, protein meal, and vegetable oil. It has a barge bulk unloading jetty that is equipped with two grab operating cranes (so containers could also be used). The current company was founded by shareholders in 1996. Its operation started in May, 1998. Module 2 was added in 2005 which allowed oil processing to reach the capacity of 19,000 metric tons per day. This oil is then routed either to the refinery or for direct export. Earlier, the first 56 hectares of land purchased was utilized to build two silos and an elevator in the south berth. The first ship loaded for export was in 1987. The barge unloading facility started in 1990. The newer north berth has a total storage capacity of 730,000 tons for dry products and 400,000 tons of soybeans for processing. A tank farm can store vegetable oils. Capacity as of two years ago was 147,600 tons—statistics for current capacity were not readily available. Work to improve the depth of the Parana River may soon allow the waterway to have an available draught of 34 feet. With this improvement, ships could load full cargoes rather than partial Panamax loads from the Parana River. However, because the Parana River silts so badly, dredging would have to be a continual process. Additional storage and unloading capacity are currently being worked on at Terminal 6. Access to Terminal 6 is provided by more than nine major roads, the Parana River and railway transportation. Shipments of soybeans from Paraguay and Uruguay are from up the river or down the river respectively.

February 20th, Wednesday

Estancia Carmen, once owned by the famous King Ranch is now run by a farmer corporation known as AdecoAgro and is located in Venado Tuerto in southern Sante Fe province. It employs a technical agronomist and is a very intensively run farm. The farm grows soybeans, corn, popcorn, grain sorghum, sunflowers, wheat and alfalfa; and also has a modern dairy complete with a new milking carousel, automatic milkers, and shade barns equipped with cooling sprinklers. This farm has what is characterized as some of the most productive soil in all of Argentina. Canals cut through the farm pulling excess moisture from cropland and feeding needed water

into the nearby town. New equipment, mostly of Argentine origination, is utilized and new commercial seed varieties allow productivity to be good. Although Argentines do not eat popcorn, it is grown here for export. Often exported to Mexico, it can then be bagged and sold as a local or national brand (e.g. Reddenbocker’s--in the United States). Soil sampling and use of new information from the United States are utilized at Estancia Carmen. Both web browsing for agronomic information as well as training in the United States has allowed this corporation to grow and become more efficient. According to the farm's managers, much of Argentina’s advancement in agriculture has been made based on American agricultural research and development.

into the nearby town. New equipment, mostly of Argentine origination, is utilized and new commercial seed varieties allow productivity to be good. Although Argentines do not eat popcorn, it is grown here for export. Often exported to Mexico, it can then be bagged and sold as a local or national brand (e.g. Reddenbocker’s--in the United States). Soil sampling and use of new information from the United States are utilized at Estancia Carmen. Both web browsing for agronomic information as well as training in the United States has allowed this corporation to grow and become more efficient. According to the farm's managers, much of Argentina’s advancement in agriculture has been made based on American agricultural research and development.

February 21st, Thursday

The team departed for Rojas to tour the Monsanto seed plant located there. This seed plant is considered the largest in the world. Recent renovations include a huge cooling facility which is equivalent in length to a city block. Plans exist for further expansion. Corn processing for seed was ongoing, and shipments to Illinois and Indiana were ready for loading onto trucks. This is one of the few facilities that fill 50 pound sacks of commercial corn seed for planting in both the United States and Argentina. The seed going to the United States is separated into small, flat seed; small, round; large, flat; and large-round seed for customer use. On the other hand, with the Argentine planters, the seed is simply separated into two types, small and large. Corn seed that had been processed that day was for the American market. It was some of the new biotech, three-way products that included weed and two insect genetic modifications. On the other hand, biotech corn allowed to be used in Argentina has only a two-way (weed and one type of insect control) or are single (Roundup-Ready) genetic modification. After processing corn during this earlier harvest, the facility would go into soybean bagging and processing.

Security at the Monsanto seed plant in Rojas is tight to prevent seed approved for use in the United States, but not in Argentina, from being used in Argentina, where the seed could be quickly and easily utilized because Argentina has a similar climate to the United States.

Security at the Monsanto seed plant in Rojas is tight to prevent seed approved for use in the United States, but not in Argentina, from being used in Argentina, where the seed could be quickly and easily utilized because Argentina has a similar climate to the United States.

At Pergamino, the team toured several of the farms that grow seed for Monsanto in the region. Integrated pest management procedures were utilized in corn, soybean, grain sorghum and sunflower fields. Argentina had only about 16,000 square kilometers in irrigation in 2003. Now double or triple that is under irrigation. Much of it land that companies have developed for seed production. In Argentina the median age is 29 years as compared to 36 in the United States, and farmers tend to be younger than in the United States. There are 23 provinces within Argentina but the most productive areas for crops are in Cordoba and Buenos Aires.

One recent development in agriculture has been the use of silo bags for grain storage. In the past, Argentina has had very little storage which has necessitated grain export during harvest rather than holding grain for better pricing or buyers. The farms obtained some of their new technology through interaction with Argentina's experiment station system, INTA (Institutio Nacional de Technologia Agropecuaria). There are farms with many types of business organization in Argentina. Some are large farms run by proprietors, more are run by managers, there are medium to average sized farms run by land owners, some are groups of small farms organized by a single farmer, others are organizations that contract annually to run groups of small farms, some are run by farmers that run other farms also, some small ones are run by farmers who only run their own farms, some are where work is done across farms utilizing custom work for almost all operations, and there are some with yet other forms of organization. One farm visited by the team was divided into various fields, mainly for the growth of commercial seed increases for Monsanto, and had custom combiners that harvested the crops. During the visit, corn was being harvested around scattered rain showers.

One recent development in agriculture has been the use of silo bags for grain storage. In the past, Argentina has had very little storage which has necessitated grain export during harvest rather than holding grain for better pricing or buyers. The farms obtained some of their new technology through interaction with Argentina's experiment station system, INTA (Institutio Nacional de Technologia Agropecuaria). There are farms with many types of business organization in Argentina. Some are large farms run by proprietors, more are run by managers, there are medium to average sized farms run by land owners, some are groups of small farms organized by a single farmer, others are organizations that contract annually to run groups of small farms, some are run by farmers that run other farms also, some small ones are run by farmers who only run their own farms, some are where work is done across farms utilizing custom work for almost all operations, and there are some with yet other forms of organization. One farm visited by the team was divided into various fields, mainly for the growth of commercial seed increases for Monsanto, and had custom combiners that harvested the crops. During the visit, corn was being harvested around scattered rain showers.

February 22nd, Friday

At Junin, the Ministry of Agriculture (SAGPyA) employee for the Junin delegation discussed some of the problems being seen in the soybean crops around the area and some of the concerns of the delegation's farmers. In particular she discussed the soybean fields being checked and sprayed for the green caterpiller in the region. Crop conditions in the field were mentioned including some late frost that had occurred earlier in the season. Reporting from these regional offices of information learned from contacts and with field checks to headquarters are put into the biweekly bulletin published by the Secretary of Agriculture. Argentina continues to improve in productivity and technology advancement in agriculture; however, certain limitations, such as transportation of product for export have hampered progress.

Current USDA area and production estimates for grains and other agricultural commodities are available on IPAD's Agricultural Production page or at PSD Online.

|